HorizontalDirectionalDrilling

Horizontal directional drilling techniques are used for the steerable installation of new pipelines, ducts and cables.

The term applies to a crossing in which a pilot bore is drilled, and then enlarged to the size required to accommodate the product pipe. The drill path may be straight or gradually curved, and the direction of the drilling head can be adjusted at any stage during the initial pilot bore to steer around or under obstacles.

Normally launch and receipt pits are excavated so as to collar the hole and collect drill slurry and cuttings. These pit dimensions vary according to the size of the rig and conduit/pipe to be installed.

The installation of the product pipe is usually a two-stage operation. A pilot hole is drilled along the required path and the bore is then reamed in either a single or multi-stage operation (subject to pipe size and ground conditions) to a larger diameter to accommodate the product pipe. During the final ‘pullback’ stage, the product pipe is attached to the reamer by means of a swivel connector and is pulled into place.

All HDD machines use a drilling fluid, which lubricates and stabilises the bore, and also conveys the excavated material in suspension.

The HDD Process

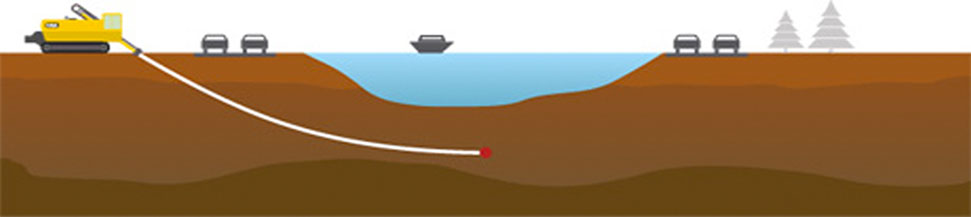

Pilot Bore

Starting at the entry point a drill head, suitable for the ground conditions, is drilled along the predetermined route with depth and alignment monitored continuously.

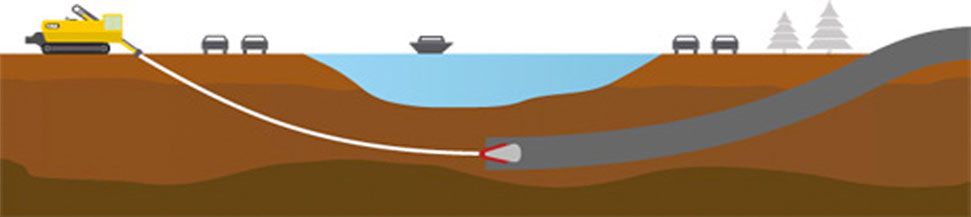

Reaming Process

The pilot bore is enlarged in suitable steps by back reaming the hole with cutters designed for the ground conditions to a size that accommodates the product pipe.

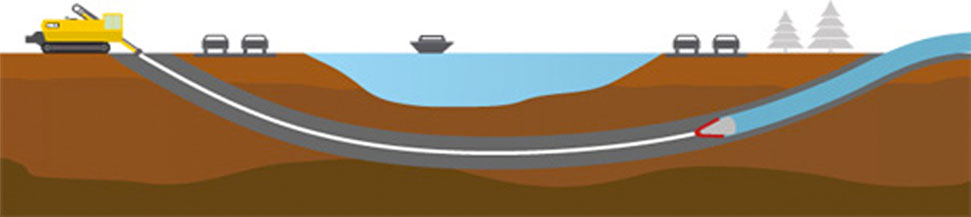

Pipe Installation

Once the drill string is connected to the pipe via a swivel pull back commences. In some instances the pipe can be pushed into place.