Scope of Works

REMS Stage 1B involved major upgrades to Bomaderry and Nowra WWTPs to increase both the capacity and level of treatment at each site to achieve high quality reclaimed water suitable for either beneficial reuse or discharge to receiving waters. UEA’s work under contract included a 2.9km transfer main to allow reclaimed water to be transferred between Bomaderry and Nowra WWTPs for final disinfection and to transfer the combined reclaimed water flows from both WWTPs to the existing REMS distribution system.

UEA’s engagement on the project was specifically around two distinct deliverables: Milestone 5, the performance of the Pipeline Design Development Services, and Milestone 6, including the construction and commissioning of the proposed pipeline connecting the Bomaderry WWTP to the Nowra WWTP. Contracted by UGL for Shoalhaven Water, UEA’s involvement in the project commenced with early contractor involvement, through to tender submission, optioneering and then into the overall construction phase. Although not a mandatory part of the overall scheme, the Bomaderry to Nowra transfer pipeline had several significant hurdles to overcome before being approved for construction.

Milestone 5 required the development of the overall Bomaderry to Nowra pipeline taking the plans through to a 100% Issue For Construction design based on further geotechnical data, consultation with stakeholders, review of suitable pipeline materials, performance criteria and construction methods. This collaborative process was undertaken over an extended period of time, allowing input from the overall client, contractors, operators and impacted stakeholders.

Construction

The letting of Milestone 6 to UEA was a fulfilling achievement given the level of works put into the pipeline design from initial concept and through all design phases. As our team was involved from the beginning, we developed a comprehensive understanding of the project which created an ease and level of trust between the client, principal and contractor so works could progress without delay.

Responsible for the end to end construction of the nearly three kilometre pipeline, UEA established site compounds – one with an engineered sound wall – and commenced construction to condense the already ambitious works program. The critical path of the project (1,410m in length) had always been the major HDD crossing of the Shoalhaven River and we expected to encounter a mixed bag of ground conditions including sand, silt, clay, gravel, cobble and hard metamorphic rock.

In order to help manage the unstable and problematic overlying ground conditions, steel conductor casing was seated fully into rock from the entry side to prevent both the intrusion of overlying soils and the escape of drilling fluids to the sensitive marine environment. Additional geotechnical boreholes undertaken during the design phase had shown loose soils, gravel and cobble present and informed a casing length of up to 130m – a length never previously undertaken by UEA. Casing installation was successfully completed to 129m from the rig, utilising a variety of methods and casing sizes.

As works were in close proximity to residents and sensitive receivers, both working hours and noisy activity were tailored to help reduce impact and minimise disruption, providing respite where the drilling and construction processes would allow.

Challenges

Commencement of the pilot bore, the guided portion of the HDD works, started as planned and proceeded well until approximately 550 metres out from the drill rig. Historical geotechnical borehole logs and seismic data inferred that the rock profile was horizontally planed, but during the pilot hole construction an ancient paleo channel was encountered, resulting in potential fluid loss given the extended length of the bore. Works on site ceased while calculations to allow the pipeline to be installed deeper were confirmed. The pilot bore was then recommenced at a level ten metres lower than the previous design and successfully completed in rock across the Shoalhaven River, under the Manildra Group Ethanol distillery plant to the designated exit point without fluid loss to the formation.

A second maxi rig was mobilised to the northern side of the river to undertake the 24”, 610mm back ream for the 400mm PN32 HDPE pipe. Back reaming commenced shortly after the mobilisation of the second rig with the aid of a tail string to help secure the borehole at all times. Punishing conditions caused significant wear on the HDD tooling and resulted in slower than expected progression, although the overall works program was still able to be maintained.

The correlation between later geotechnical boreholes, progression rates and tooling wear confirmed rock strengths over 250mPa for the deeper sections of the bore also proved to be a challenge – this was some of the hardest rock UEA has drilled as a business.

With the completion of the pilot bore and reaming underway, attention turned to the other portions of works to be completed: three minor HDDs from 36m to 200m in length, over a kilometre of trenching in potential and actual acid sulphate soils, and the installation of associated valves, pits and fittings. Thanks to kind weather and lower than expected rainfall, open cut trenching progressed well on three fronts and allowed all minor HDDs to be tied into the overall pipeline works.

An Australian First

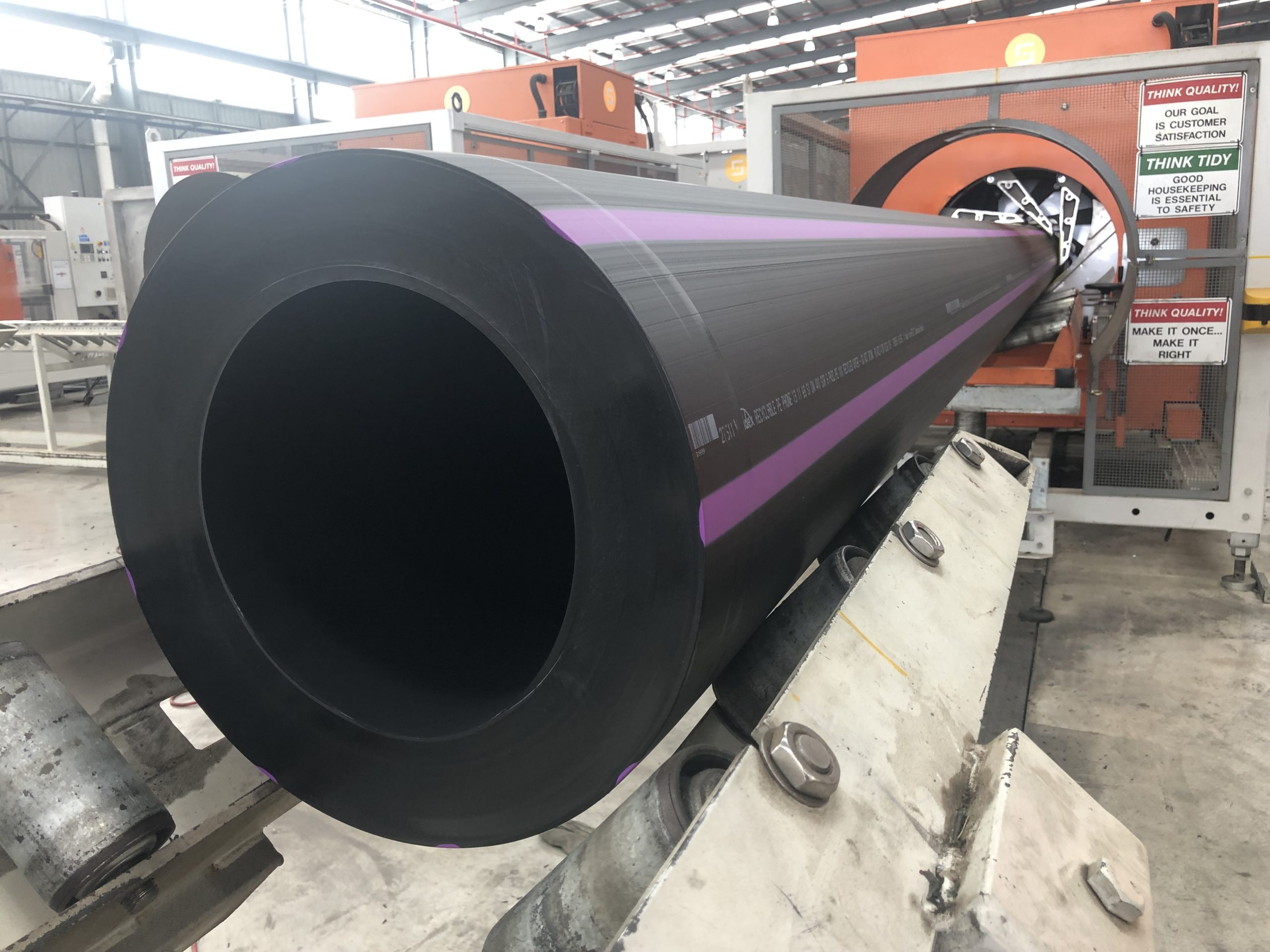

Also undertaken during for major HDD reaming operation was the welding, stringing and testing of the unique and Australian-first 400mm PN32 HDPE pipe. Manufactured by Vinidex under strict quality control standards witnessed by UEA as part of the project’s QA system, the 400mm PN32 pipe was made to European standards out of H112PC resin (PE112) and allowed for a lower slump, more uniform wall thickness and stiffer pipeline. For added security, lower risk and peace of mind an above ground pressure test was undertaken to ensure compliance with the specification as well as a rigorous 1:10 destructive weld test frequency passing all required NATA tests.

The back reaming was completed in one pass, utilising multiple reamers to achieve the final reamed borehole. At the completion of the reaming pass, a suitable sized barrel reamer was utilised to pig and prove the borehole ready for pipe installation. Although reamed by the drill rig on the northern side of the bore, the pipe was installed by a rig based on the southern side of the river due to the available pipe welding and stringing room.

Completion

Following the successful installation of the Shoalhaven River crossing, a NATA certified pressure test was undertaken to ensure that no defects were evident in the installed pipe and that all outstanding sections of the pipeline could be tied together and readied for commissioning. Given the very high water quality required to be delivered by the pipeline, a rigorous flushing and swabbing process was followed to ensure a clean and defect free pipeline was able to be handed over to Shoalhaven Water. Prior to handover a further pressure test was undertaken of the entire pipeline to test all sections for conformance and ensure that it was compliant to the specifications.

Carmel Krogh OAM who was the Director of Shoalhaven Water at the time said of the project “a great achievement by UEA – you have done a fabulous job and were the epitome of professionalism”.

Despite the numerous challenges overcome during the project, the satisfaction of a pipeline handed over on time and within budget was only matched by knowing that the reclaimed water being pumped through the REMS 1B Shoalhaven River Crossing pipeline was not only being beneficially reused, but also able to assist in managing the bushfire response to the major bushfires to hit the region in early 2020.