Scope of Works

The Parmelia Gas Pipeline is a major piece of gas transmission infrastructure linking the Perth gas fields with the Carnarvon Basin and Mondarra Gas Storage Facility. Owned and operated by APA Group, at 445km in length, including laterals, the steel pipeline is a critical piece of WA infrastructure.

As such, when two sections of the pipeline recently required replacement due to a railway expansion, the project needed to be completed promptly and with minimal disruption to service. Adding extra complexity, the 550m and 650m crossings were required to be placed under roads and within 10-20m of the active rail corridors.

Steve Hopkins, General Manager at UEA, said that given the minimal disturbance required and limited construction area, horizontal directional drilling was a natural choice for the project. “This project needed to be completed really promptly not only because of the critical infrastructure, but also because of the ground conditions. Being familiar with WA ground conditions, we are well acquainted with the running sand geology of the area, and we know the impact that it can have on an HDD project.”

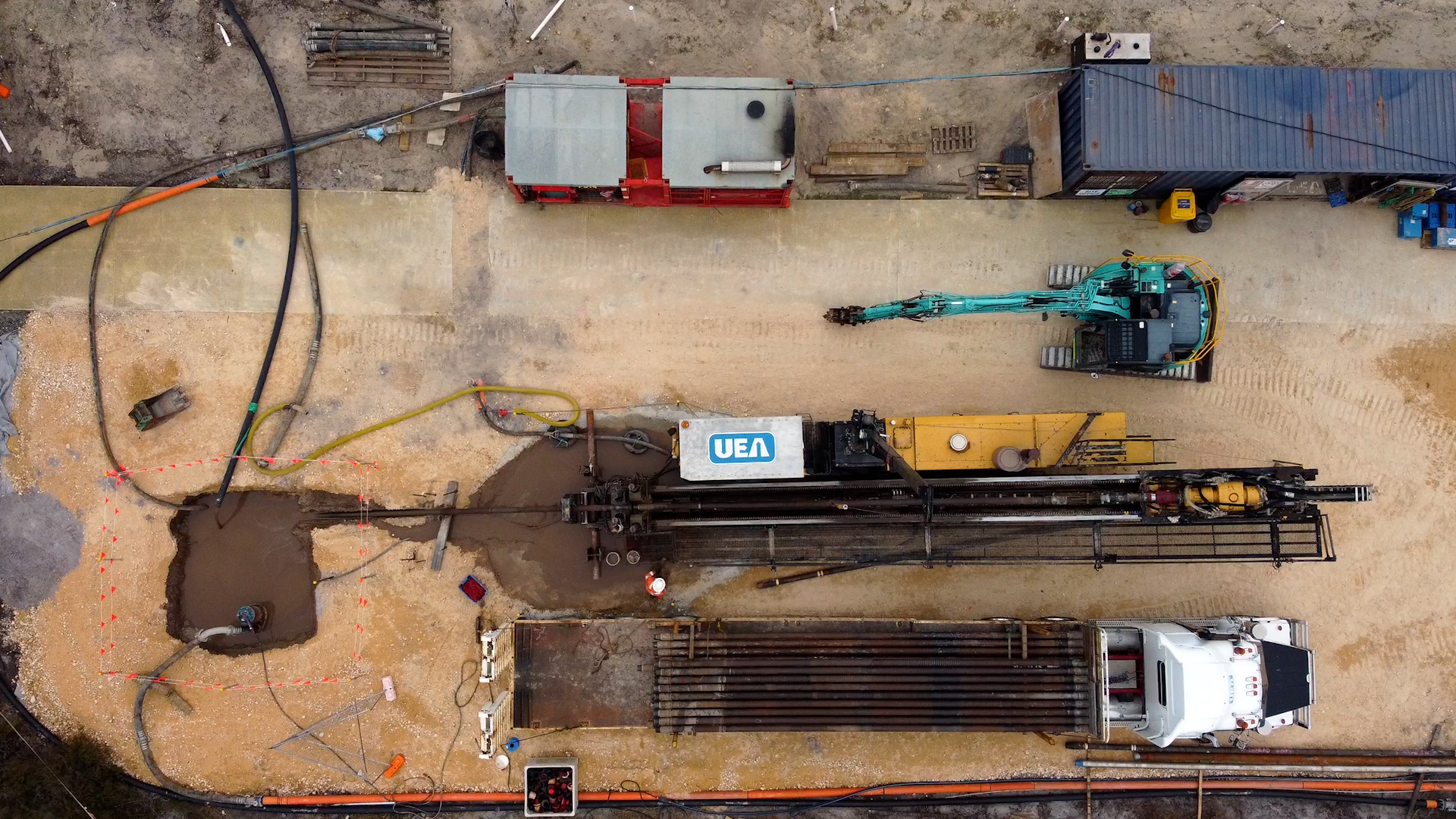

A priority for UEA (and principal contractor, Pipecraft) was ensuring that all Transperth and Department of Transport requirements were abided by, and that there were zero impacts on the road and rail infrastructure. After completing the necessary design and auxiliary planning, UEA mobilised quickly to get the project underway. UEA Operations Manager, Jonathan de Vos, said thoughtful planning of site layout was vital. “We were low on space but still needed to deliver this major piece of infrastructure,” he said. “And being a steel pipeline, the steering and drilling accuracy in particular needed detailed planning to ensure both pullbacks could be completed without adversely impacting the pipeline.”

Driller Andre Nevstad was in charge of the Vermeer D330 maxi rig, which was selected for its combination of ease of mobilisation, capacity for larger pipelines, and relatively compact size. “The D330 is great for jobs that have limited space but still need the capabilities of a maxi rig. The onboard drill cab and power pack minimises the extra containers which are normally required for maxi spreads, which is great when space is a premium.”

Spudding in on the first crossing in early May, the works took place on an accelerated schedule from there. “Progress was swift but predictable,” said Jonathan. “With the faster schedule, optimal site layout and specifically designed drilling fluids program, we minimised risk from the running sand conditions and avoided potential collapse of the holes, which can happen with delays in sand conditions.”

Installation of the two 355 mm diameter pipelines, with a total length of over 1200m, was complete within less than a month. Steve said that the successful installations were a testament to good planning. “By completing all of our planning and ensuring all factors were accounted for prior to spudding in, drilling was smooth and uninterrupted. Soft sand can be very unforgiving in the case of delay, but with proper planning and due diligence, there’s nothing to forgive.”