BACKGROUND

The Batemans Bay bridge carries the Princes Highway across the Clyde River and is the predominate thoroughfare for those travelling up and down Australia’s east coast, with thousands of private and commercial uses each day. Opened in 1956, this truss bridge provides a single lane for each traffic flow direction and with a deck height of a mere 3.6 metres, a vertical lift mechanism was installed, lifting a 23 metre section of the bridge to a clearance height of 18 metres for passing watercraft.

The Roads and Maritime Services elected to replace this bridge in order to provide an increase in capacity and a reduction in disturbances and congestion created by the existing bridges vertical lift systems. The new bridge will provide two lanes of access for each traffic flow direction and will sit 12 metres above the water surface. The bridge will be constructed out of beams, doing away with any trusses of over deck infrastructure, and significantly reducing restrictions currently in place on the existing bridge regarding freight size and loads.

UEA was originally involved in providing expert advice as part of the feasibility studies at the earlier stages of the project. This allowed for the concept design to move into the D&C engagement phase. UEA was engaged as a specialist trenchless contractor to relocate and expand the existing network of services across and around the Clyde River in preparation for the construction of the new bridge.

SCOPE OF WORKS

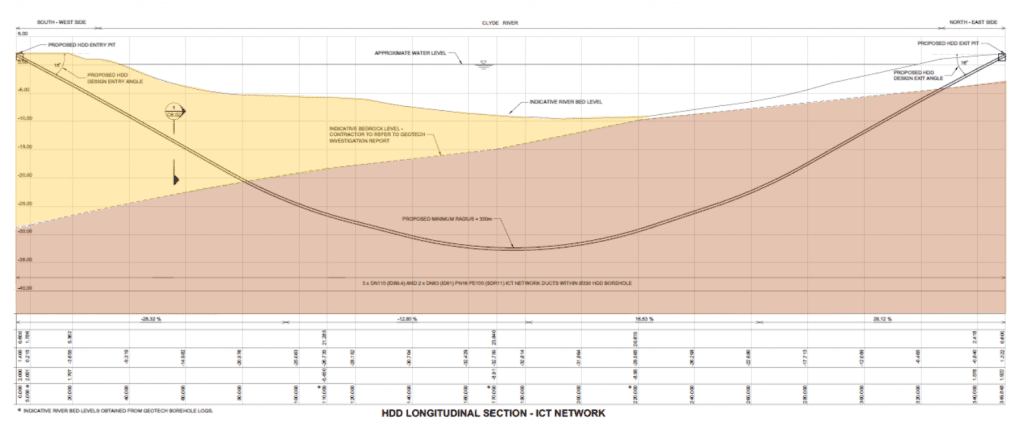

UEA was engaged as a specialist trenchless contractor to relocate and expand the existing network of services across and around the Clyde River in preparation for the construction of the new bridge. Trenchless construction methods, namely horizontal directional drilling (HDD) were used to install the awarded river crossings to avoid impacts to sensitive environmental features, such as road infrastructure crossing, river crossings and Australian Marine Parks reserved sites. Activities associated with trenchless construction techniques included the establishment of the drill launch sites, drill reception sites and pipe laydown areas. The drill reception site also required an area the length of the drill run to string the pipe out prior to the installation.

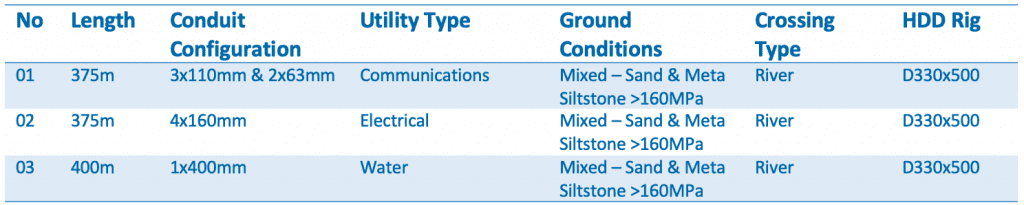

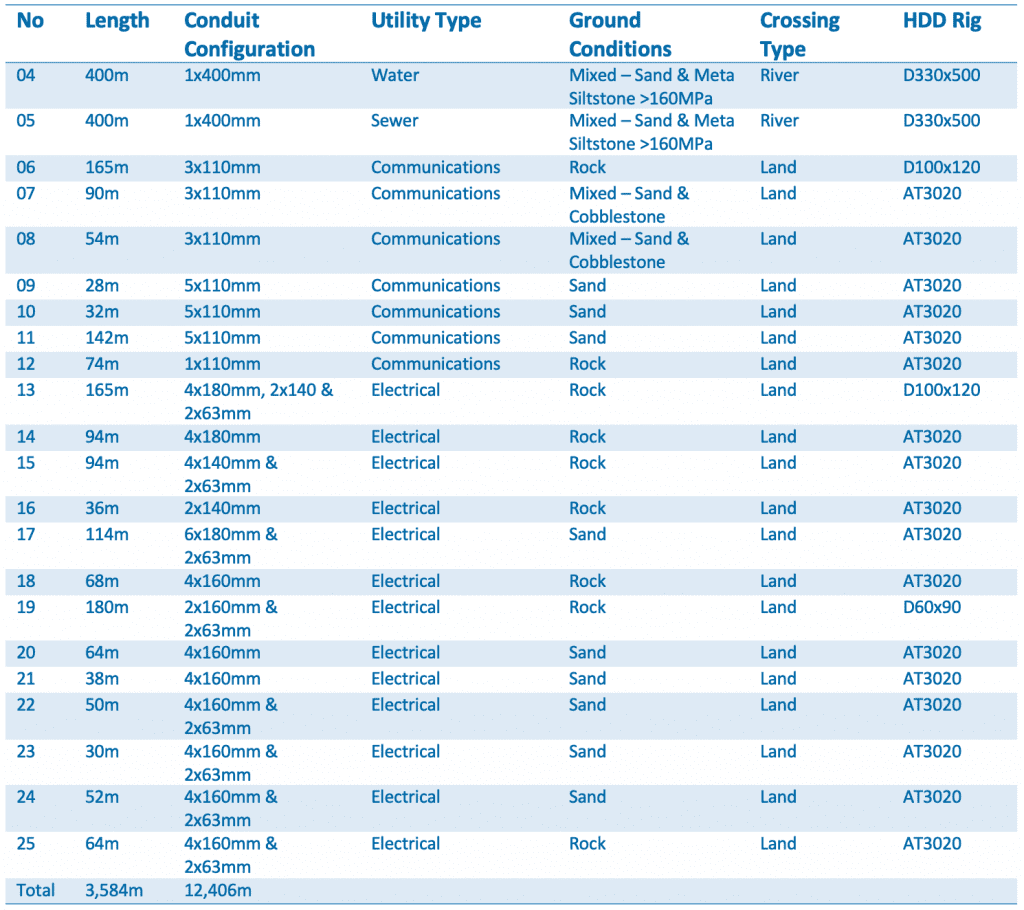

The initial scope was to deliver the following:

UEA worked closely with the client, providing advice and expertise into how the project could be optimised through safety, pricing and efficiency. Based on these initial discussions, UEA was awarded an additional design and construct scope that included:

BATEMANS BAY MARINE PARK PERMIT

A search of the Australian Marine Parks database identified that Batemans Bay and the Clyde River fall under the Australian Marine Parks protection, restricting all activities both in and around the water. As UEA’s physical presence was within 50 metres of the river’s edge, and the HDD activities occurred under the river, the potential environmental impact of the works needed to be mitigated. Due to UEA’s early contractor involvement in the project, the project team was able to design the underbore path to a depth and alignment that would mitigate – or significantly reduce – any risk to the surrounding marine environment.

Utilising our in-house expertise, UEA developed a comprehensive set of management plans that included a site-specific Construction Environmental Management Plan (CEMP) and Environmental Work Method Statement (EWMS). The objective of these management plans was to avoid or minimise the potential marine park’s impacts associated with installation of the project scope across and around the Clyde River. The CEMP and EWMS set out all the safeguards required to minimise any adverse impacts to the identified marine park areas. UEA identified a number of measures to avoid or minimise the potential impacts by erecting significant sediment and run-off controls, closely monitoring all drill fluid returns and daily inspections by the marine park rangers.

Challenges

The surface ground make-up and materials were found to be of very poor quality around the Clyde River. This required the river crossing bores to have steel casing installed to support the entry point from collapse during drilling operations, with the steps below undertaken to mitigate the potential risk of environmental impact to the various users of the Batemans Bay Marine Park (i.e. oyster farmers and habitats for a number of fish and bird species):

1. Bore design developed based on the geotechnical information

2. Local geology used as a control (bore within unweathered argillite and meta-siltstone for approximately 80% of the underbore)

3. Drilling Fluid Management Plan (DFMP) identified drilling products required at each stage of the underboring process, influenced by the geology (e.g. use of bio-degradable drill fluid will be utilised if required in areas deemed high-risk of frac out)

4. Down hole control materials were readily available to mitigate potential submarine contamination to waterbodies from frac out

5. Ongoing risk assessments were undertaken, based on the underbore designs. In particular, if the relationship of the profile to surface level in the soft formation (south) deems any areas are at high risk of frac out, and the risks cannot be mitigated sufficiently using measures within the DFMP, the installation of a steel casing in the soft formation on the south side may have been implemented