Scope of Works

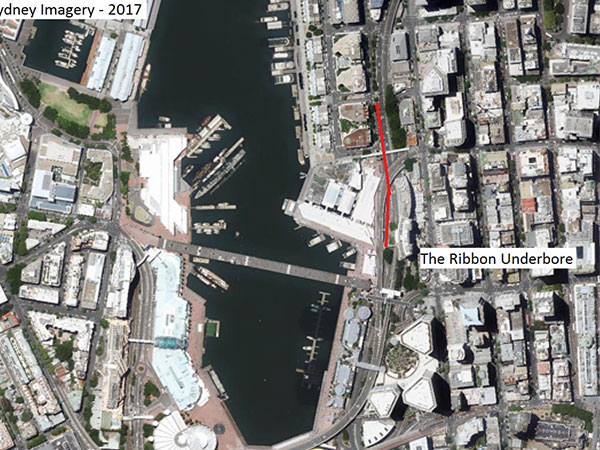

As a part of the Ribbon Development in Darling Harbour, UEA was engaged to undertake extensive utility location with the objective of relocating the existing gas main in Darling Harbour. Stage 1 involved the use of dial before you dig requests, ground penetrating radar (GPR) searches and non-destructive digging (potholing) to identify the location and depth of existing services along the proposed underbore route. Once completed, UEA utilised GIS data to complete an underbore design which mapped all existing services, the new proposed gas route and possible obstructions including the concrete footings for the Western Distributor.

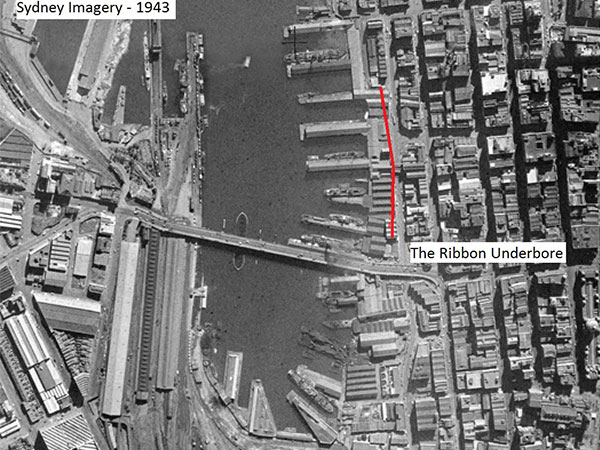

Based on UEA’s experience with completing complex underbores in highly congested locations and the completion of stage 1 works, UEA was also awarded stage 2 of the project following a competitive tender. Working within a brownfields site with over 200 years of redevelopment, historical mapping was utilised to show that the alignment of the underbore would traverse real estate that had changed significantly over the past 75 years.

Without any supplied geotechnical borehole data, the strata to be drilled could not be confirmed before the completion of the pilot bore, with the only known ground conditions to be sandstone at the HDD exit point.

CONSTRUCTION

Working at night, UEA mobilised and completed a 240 metre underbore using a Ditch Witch AT40 to install a 110mm PE100 SDR11 gas pipe. The Ditch Witch AT40 was utilised based on the anticipated mixed ground formation and the known sandstone evident at the HDD exit side. The bore path encountered a number of different ground types including building rubble, clay and sand fill, marine muds and weathered/fresh sandstone. Due to site limitations, pipe was strung out in two 120 metre strings with the final tie in weld completed during the pull back of the pipe.

COMPLETION

Despite the difficult location, high service density and out of hours working, the new gas main was installed over a period of two night shifts with limited disruption to the area.